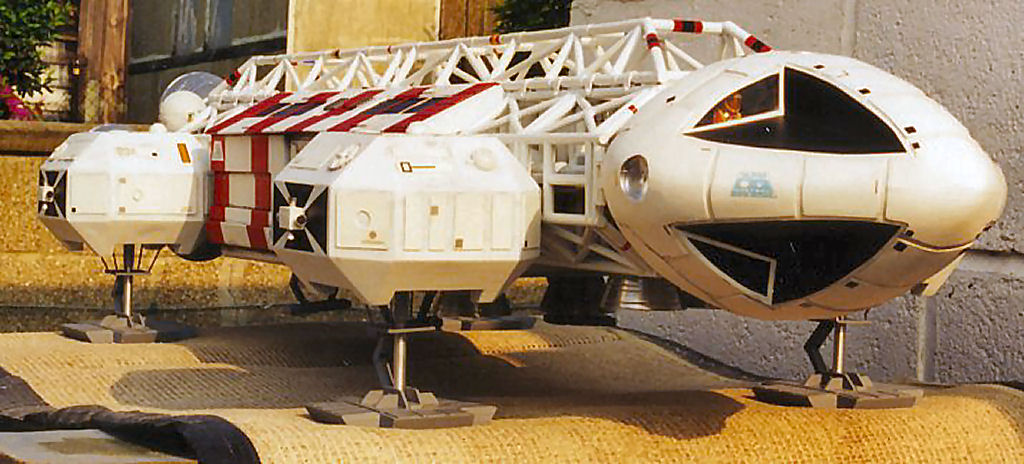

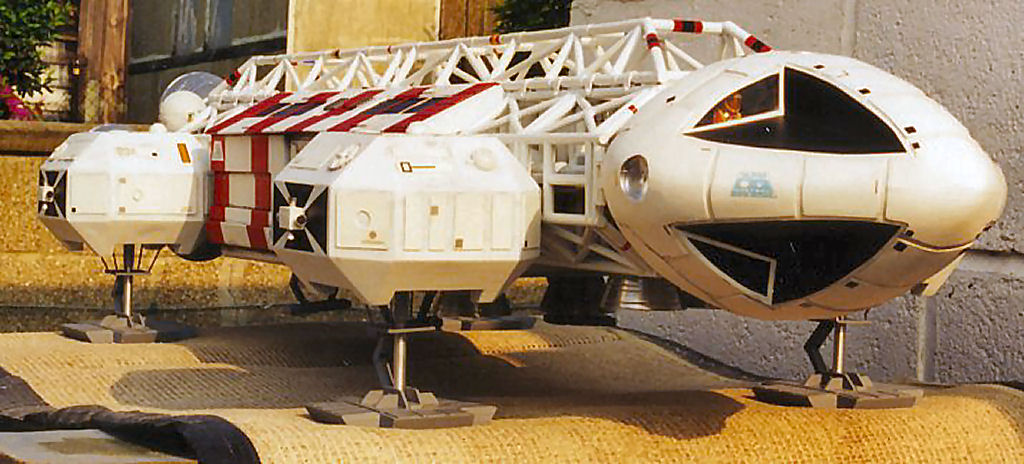

On top of that,

moulds had to be made for the parts like the

side gear pods, the main pod, beak and so on.

The beak caused me some fun and one pair of scrapped moulds.

The first attempt just wasn't, how shall I put it,

fat enough top to bottom.

So took the wood masters, built them up again and finally ended

up with summat that seemed about right as you see here.

Reference material was not easy to come by back then.

The framework as I had roughly figured out,

took almost a week just to cut all the pipe to length.

Never mind the filing the ends or the soldering up.

A long and slightly tedious affair but worth the effort in the end.