Back to the model after all that.

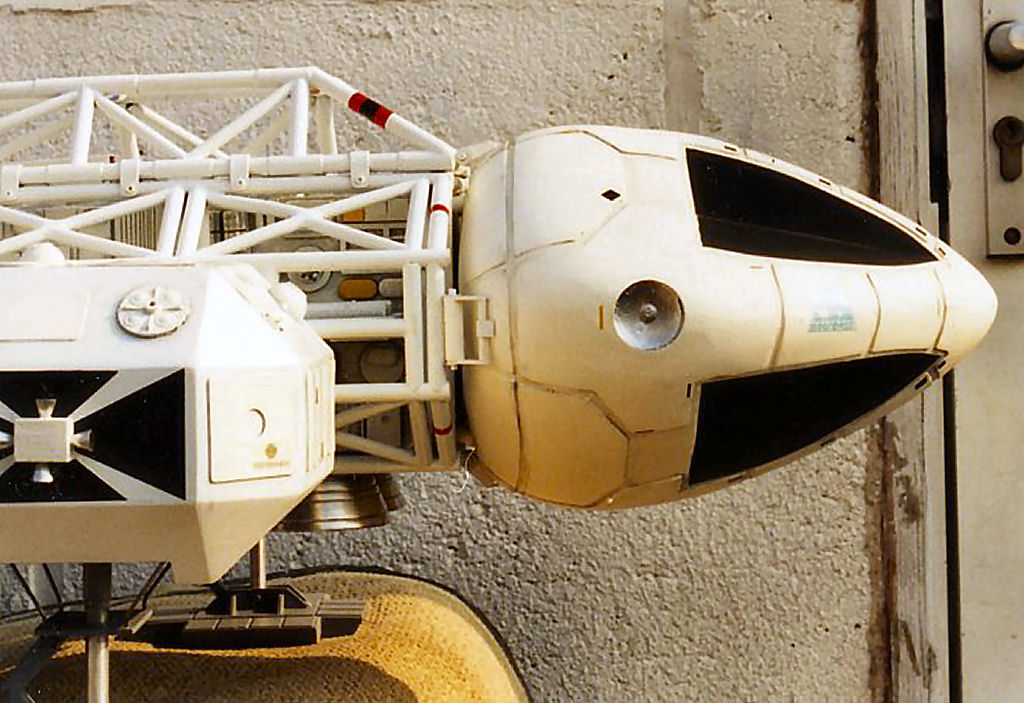

The detail parts inside the cages at each end of the spine were

designed so that one set of masters were made

and the parts would fit snugly in each end,

one end being a mirror image of the other.

Ditto with the side pods that the landing gear is mounted on.

Just one pair reversed for the other end.

Certainly saved on the mould rubber.

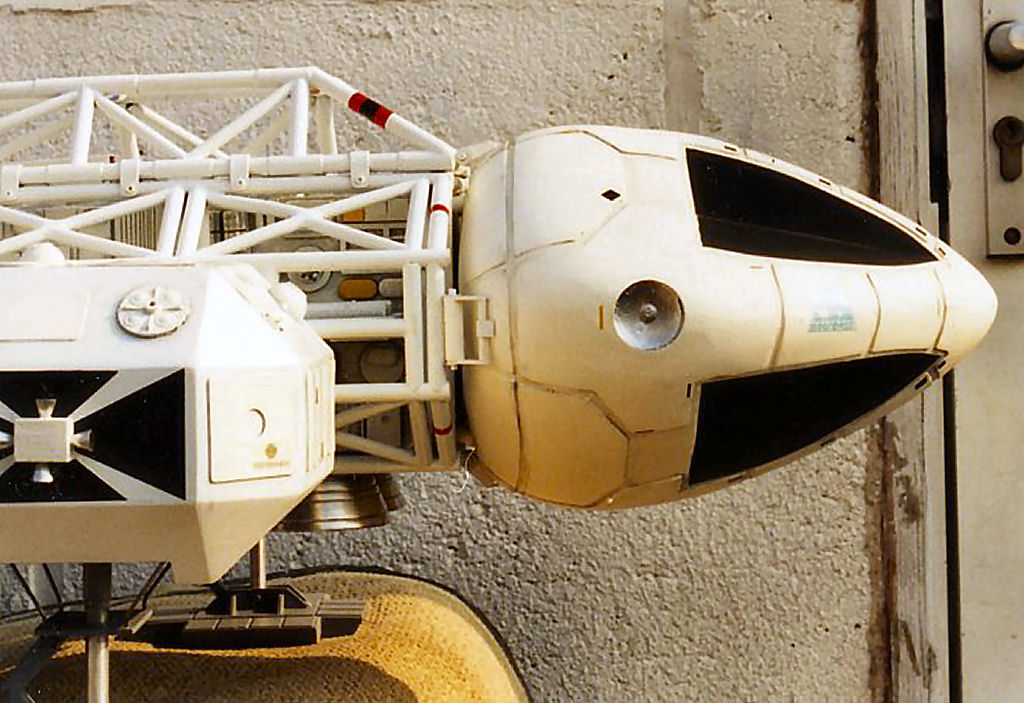

The beak was moulded top and bottom fashion.

The side and top/bottom depressions, whatever the official name was

for them I have no idea,

were marked in the castings after removing them from the mould,

then roughly cut out before assembly.

Once assembled it was a simple task of putting two part mixed automotive putty

down the holes which were covered to a shallow depth with the

interior detail walls and then pushing in a shaped rubber plug,

the putty cured,

the plug removed,

edge cleaned and then painted.

Yes, it is really as simple as that.