Polarlights Enterprise 1701-A Refit

1/350th Scale

Page Number

Page Number

Last But By No Means Least...

Last major assembly and lighting bit here.

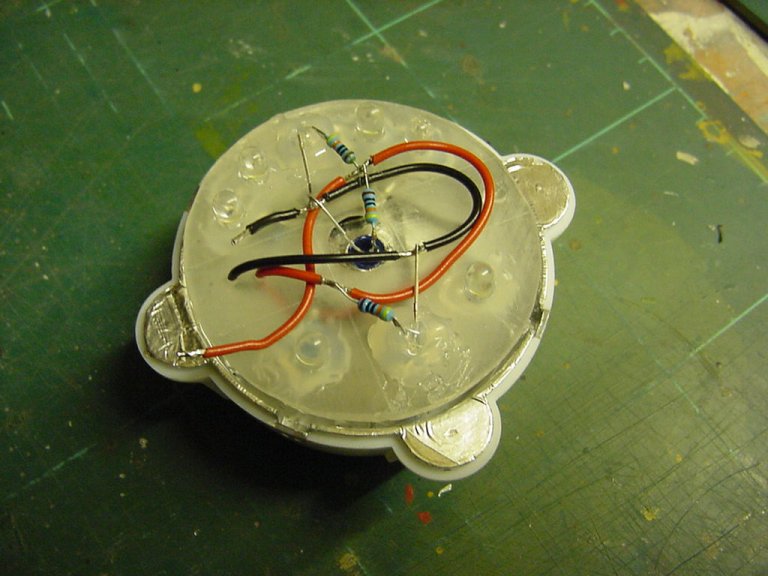

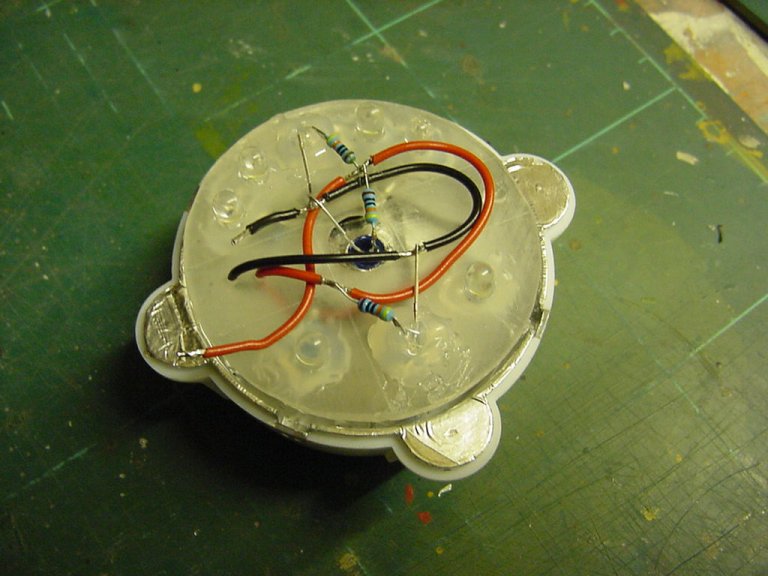

Simple disc of 2mm clear styrene duly fitted with six 5mm LED's facing back and two facing front,

mucho soldering and insulation then hooked up to the LED lighting the deflector,

joined up to the main power feed and then glued into place.

At this point some lighting power testing was in order.

Thanks to some very helpful info from a Hobbytalk member,

cheers JT!,

the in's and out's of the voltage/amp details got sorted.

Reckoning on using 12 volt supply and each LED rated at 3.4v 20

it came out that to provide full power to all main LED's would take a rather large 3.12 amps.

A bit much and would cause some possibly destructive heat buildup problems inside the model,

i've opted for a maximum of 12v at 2 amp supply though I may decide to downgrade

the volt/amp supply as this will all be dictated by how well or otherwise

the light shows through after all the painting is done.

Much still to be sorted so stay tuned my friends, all may possibly become clear later...I hope.

Well I Only Got Two Arms...

Well now to the next problem in this wee tale.

This model ain't exactly small or lightweight and the painting and decaling will not take a small amount of time.

Now holding it up to do all this will most likely mean I will end up with a right arm being a

bit tired from all the fiddling about and a left arm like Arnold Schwarzenegger...

not really a decent option as I would just end up looking silly.

Nothing new really but a solution had to be found to support the model

and allow yours truly to work on it.

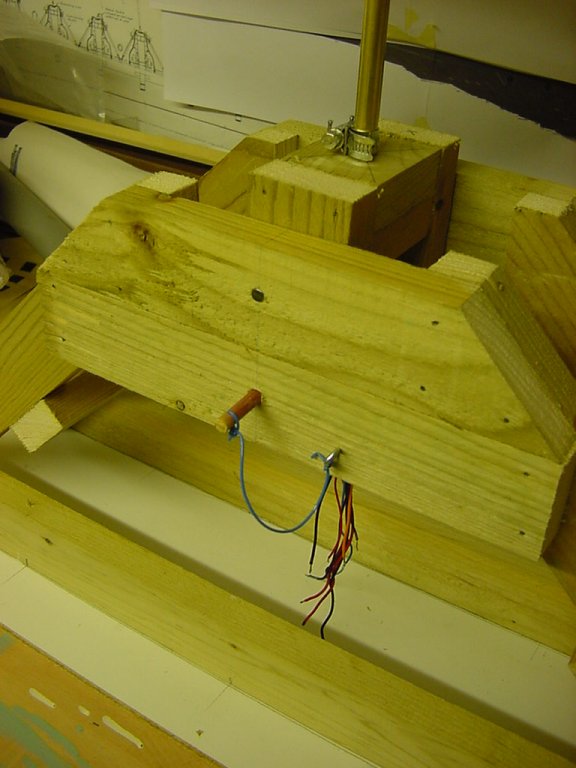

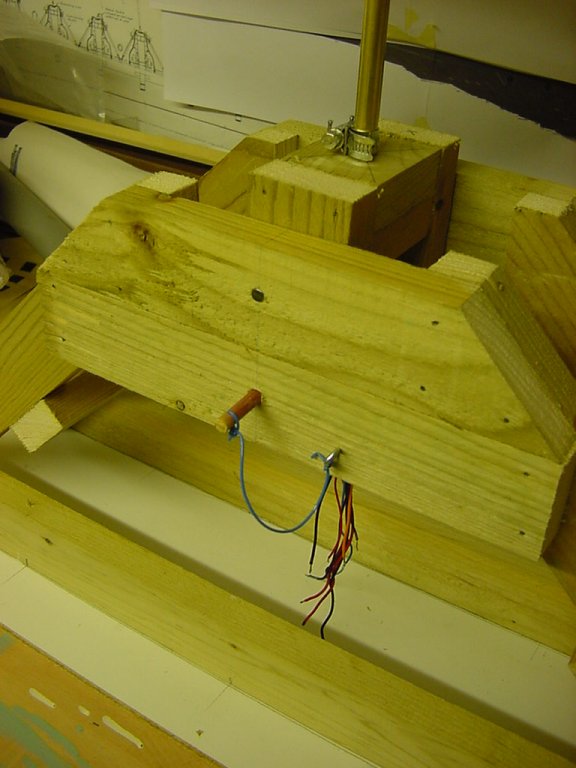

After a bit of sawing malarkey with some 2 x1 timber, a goodly dollop of glue and nails this was the result.

Simple, crude and and a bit rough around the edges but does the job...

hold on, someone said that about me the other day...oh well.

The center part is made to pivot front and back so the model can be tilted so makes it easier

for me to get to the relevant parts for slapping on some paint or decals.

Just two 5mm dowels left and right more than adequately hold the deal upright and the

jubilee clip makes sure the stand tube doesn't slip down.

Some well placed nails around said clip keep the model from turning right or left,

in short the bugger will stay put while i'm soddin' about with it.

So last bit's of assembly done, all filler sanded back, all filled in panel lines re-scribed and after a shower and scrub down,

she's in the rig and ready for her next round of molestation at my hands.

The three little detail parts that fit in the left/right/bottom recesses around the main sensor dish

will be left off untill i'm almost done with painting, painted separately then fitted.

Lastly for this update, a quick look at the rear tilt...

And the forward.

Now if that don't make sure I can get to all of the model without having to hold it by

one hand and leave grubby fingerprints all over it then I give up.

That's it for today's hellhole hoo-ha.

She's going to be left for a day or two to make sure that any water that may have

found it's way inside has plenty of time to dry out before I go any further.

The next stage will be mucho masking, final light bleed taking care of then

painting and decaling proper, should be a giggle...kinda.

You goodly lot go easy now!

Page Number

Page Number